First, here's a discussion of how shorter barrels negatively impact the GPC concept, relative to 7.62 NATO. One might think that if a GPC equals 7.62 NATO in capability from a 24" barrel, that the same round should equal 7.62 NATO if both are shot from 16.5" barrels, right? This is not in fact the case. What can be seen here is that 7.62 NATO retains its energy at range more gracefully as barrel lengths get shorter than a 6.5mm round.

The way the model is set up, 7.62 NATO data was pulled directly from empirical figures, and in either case - 24 or 16.5" barrel - the 6.5mm's velocity was adjusted to match the energy at a kilometer.

Perhaps this is somewhat of an opaque example, and I should later go into greater depth exploring it, but for now, I am just reposting it here:

Alright, here you go guys, here's a demonstration of how shorter barrels hurts the GPC more than 7.62 NATO. Let's use Rifleshooter's test of Winchester contract overrun as a baseline. So, from a 24" barrel, that ammunition produces a muzzle velocity of 2909 ft/s. Here's what it looks like at a klick:

445.9 J, that's what we have to match with the GPC. I am using a 6.5mm near-Balle D homologue for this, i7 FF of .889 and a G7 BC of .249, 108gr/7g. I adjusted the velocity until it matched 7.62 at a klick from a 24" barrel:

That the MV ended up identical to .264 USA is coincidence. Note that the projectile used is much, much finer. So the round has to produce 2,875 ft/s from a 24" barrel to match 7.62 using that exceptionally fine bullet. Now, from a 16.5" barrel, the Winchester produces 2,682 ft/s:

410.3 J. So we have to match that with our 6.5mm:

So there you have it. Internal ballistics aside, even the best 6.5mm GPC loses out to 7.62 NATO as barrels get shorter. Note that 7.62 NATO retained 92% of its muzzle velocity when the barrel was shortened by 7.5", but to catch up to that, the GPC has to cling to over 97% of its muzzle velocity.

Next is a post I wrote addressing the idea that 7.62x54R "overmatches" 7.62 NATO to any substantial degree. This is a commonly held view, but it appears to be the product of some suspect ballistic coefficient figures posted to 7.62x54r.net:

The most common light steel cored ball ammo has a BC very similar to M80, and generally speaking a slightly lower or equal muzzle velocity.

I would be very surprised to hear that the more exotic types - especially the 7N1 - were at all common in Afghanistan, and I also have doubts about their "legendarily" high BCs.

For example, let's take the 7N1 "sniper" ball, pulled bullet alongside propellant and case below:

Clearly not a bad bullet shape, but how good is it? The ".249 G7 BC" figure was translated from G1 BC from 7.62x54r.net's website, the same site where I took this image. In fact, the round in this image was pulled from the very same sample of rounds tested. So there is no question that the data matches the projectile. But does the data make sense? In short, no. A .249 G7 BC means this 152gr projectile has a .907 i7 FF. What other projectiles have about a .907 i7 FF? Well:

The best, most streamlined examples of the 7.9mm sS Patrone had an i7 FF of about .906. And,

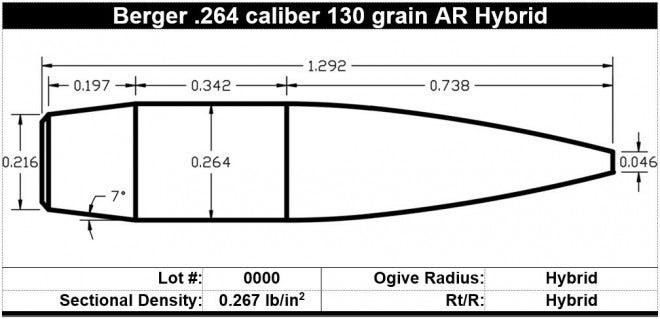

The new Berger 130 AR Hybrid ogive bullet, with its i7 FF of .919.

Both of these bullets are considerably better streamlined than the 7N1. Coming at it the other way, let's look at the plain-jane steel-cored light ball projectile, which according to 7.62x54r.net has a BC (converted) of .163 G7, which would give it a hilariously poor i7 FF of 1.34:

Note that the ogive is identical to the tangent ogive of the 7N1, and that the boattail is not too much less severe.

Because of this, I cannot consider 7.62x54r.net's BC figure for the 7N1 to be likely. It's much, much more likely that the i7 FF of these projectiles is in the 1.10-.98 range, giving the 7N1 a BC of .229 G7, at best. Given the lower velocity, this makes it ballistically extremely similar to 7.62x51.

If you look at Hodgdon's numbers for 7.62x54R and mate those with 7.62x54r.net's BC figure for the 7N1, the round looks quite scary, but the velocities produced by actual military ammunition, coupled with more realistic estimates of the BCs of military projectiles give much more sedate ballistics.

The only way that the Russian caliber could be overmatching 7.62 NATO substantially would be if Russian AP ammunition were finding its way into the hands of enemy combatants. Not only is there little evidence that this is happening, it means the correct response would be to field a round with more penetration than current M80 Ball - which is exactly what the US Army has done with the M80A1.

Another post addresses the danger of over-emphasizing the need for fine projectile shapes. Certainly, projectiles should have as fine a shape as feasible, however often a fine shape is not compatible with other requirements, such as the shape of an armor penetrating core:

That doesn't really make sense. The shorter ogive was chosen because the ogive they were using - retained from the earlier .30-06 M2 - was short enough that the bullet could be buried more deeply in the case. Later, the form factor was improved by going to a 10-caliber secant ogive.

The 7.62x51 NATO was further specifically designed for a 700m danger space requirement, falsifying what you said about it being designed for shorter ranges. Even if I've misunderstood you and you were referring to 5.56mm, that round was designed for a 500m requirement.

You cite the 7.9x57 sS Patrone, but that round is the exception, rather than the rule. The 7.9x57 was not designed with an ogive that long; the earlier S Patrone being almost identical in shape to the aforementioned M2 Ball. The fine ogive of the sS ball was applied later, and they mostly got away with it because the 8mm projectile was so wide. The AP core for the SmK round is in fact smaller in diameter than that of the .30 caliber M2 AP, despite the projectile being .381mm wider. It could not be any wider, or else it wouldn't fit into the fine form factor - the same form factor as the sS Patrone.

So you can see that having a fine ogive has consequences, which is why even in rounds like the 6.5x55 Swedish Skp. Ptr. 41 the ogive is not that long, surprisingly. This all goes back to what I've been saying for some time now; while it's nice to have a fine ogive shape, at the end of the day having the finest projectile shape with the lowest i7 FF puts limitations on your projectile design, and less elegant projectiles not bound by those limitations may actually perform better.

It's also worth noting that the shape of the projectile of one kind of round influences the shape of others. A poorly shaped tracer projectile may not match the trajectory of the ball round closely enough, and an AP round that required a different zero than the ball ammunition would be much less useful than one that didn't. At the end of the day, all these requirements must be met, and these can drive poorer projectile shapes than the GPC crowd often assumes.

This next post is an explanation of why it is difficult or impossible to compensate for a lack of MG teams by augmenting the capabilities of the rifleman's weapon:

I think it's worthwhile, too, to take a tangent and discuss why rifles firing more powerful ammunition cannot compensate for a lack of machine gun teams. I'll make it short, I hope.The subjects of these posts will probably be combined at some point in a larger more in-depth article for The Firearm Blog, but with the Light Rifle and daily posts currently occupying my time, I cannot say when that post will arrive.

The machine gun team consists of the gunner and assistant gunner, which - like a sniper and his spotter - gives it much better situational awareness than a single rifleman. Both the gunner and assistant gunner are well-trained to make the most of this relationship, and are equipped to provide fire at longer ranges, and are given a tripod and tracer rounds to assist them in this. When you hear things like "800m is crew served weapons range" this is what is meant. Two men with the right equipment can provide accurate fire out to much longer distances than is possible with one person with a rifle, in combat conditions.

For example, let's examine what happens when the trigger is pulled against a target at longer ranges (over 200 yards). The hammer falls, and the cartridge ignites. Immediately, the gun begins to recoil under great acceleration, and flash and blast emanates from the weapon's muzzle, obscuring vision for just a moment. Within that moment the round has traveled a considerable distance downrange, and the further out it impacts, the less visible the impact is, both because the impact is more distant and because there is less velocity to the impact. The round will most likely not hit the target, due to a wide variety of errors that are impossible to consistently compensate for on the first round. If this is a rifleman, he is likely to blink during firing, and the recoil of the gun disturbs his sight picture - his rifle is after all not equipped with a tripod, and his ammunition is not (usually) traced, so he has a harder time distinguishing the trajectory of his fire. Now, if this is a machine gun team, the AG is sitting there watching all this happen. He has seen where the round has gone, as much as is possible, and the gun is properly equipped with a tripod and tracers, not to mention a T&E mechanism. Being a machine gun, too, fire comes in bursts, improving the probability of a hit. The AG is dedicated to assisting the gunner in putting out accurate fire - he has no other job (besides keeping the gun fed). His eyes help the gunner pick out targets, and he's able to tell the gunner immediate feedback that the gunner otherwise would not have - like when a civilian is sighting a rifle in on the range, having a spotter is a huge help; at longer ranges it's essential.

So for this reason, I strongly contest the idea that a lack of MG teams can be compensated for by issuing more powerful rifles. No, a lack of MG teams can only be compensated for by fielding more MG teams.